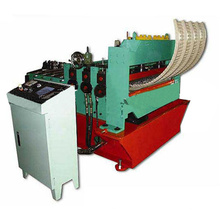

High Speed Angle Roll Forming Machine (up to 5mm)

High Speed Angle Roll Forming Machine (up to 5mm)

| Payment Type: | L/C, T/T, Money Gram, Western Union |

|---|---|

| Min. Order: | 1 |

| Productivity: | 300sets/Year |

|---|---|

| Place of Origin: | Jiangsu, China |

| Supply Ability: | 300sets/Year |

| Certificate: | SGS, ISO9001, CE |

Basic Info

Model No.: Roll Forming Machine

Product Description

Model NO.: Roll forming machine Forging Forming Method: Mold Forging Feature: High Efficiency Warranty: 12 Months Advantage: Use Widely Color: Blue and Yellow Trademark: Saibo Origin: Jiangsu, China Type: Rolling Machine Power Source: Electric Certification: SGS, ISO9001, CE Customized: Customized Condition: New Speed: Max 30m/Min Specification: CE, SGS HS Code: 84552210 The production flow of equipment

De-coiler→ feeding & guide→roll forming→straighten→post track cutting →manual out table

Feeding & guide→roll forming→straighten→post track cutting

Feeding

Armed adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener.

Entrance table-guide: Adjustable

Entrance width: 35-130mm (according the final design)

Entrance and guide roller: Diameter is ¢ 76mm, material is sae1045, HRC48-52° Surface with chrome

Forming Section

Profile steel thickness 2.0-5.0mm

Main motor power: 22Kw, AC motor, side motor to save space (Brand: Siemens which made in China)

Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

Roll station: 8stations +1 station of straighten

Roller material: Gcr15, 58-62, HRC hardness and chrome plated surface

Shaft diameter: ¢ 85mm material: SAE1045

Machine roll forming speed: 0-30m/min

The min. Roll forming Speed: 0m/min

The maximal roll forming speed: 30m/min

Roll former has leveling bolts in the base for adjust the leveling

Machine base frame adopt H beam welding steel

In the main Roll Forming Machine have 1 button for urgency stop if happen any malfunction.

Transmission: By gear box, joint with coupling, gear inside box structure is bevel gear

Machine stand adopt cast iron

Straighten device:

One station after roll forming,

Function: For revise the end product up and down/ left and right to straightness

Roller material: Roller material: GCR15 quenched 58° -62° Finishing turning CNC

Adjust by hand wheel

To avoid accidents, the drive parts will be covered by protective cover

Post track cutting system

Cutting after forming: Cut the sheet after roll forming to required length

Cutting Type: Hydraulic servo motor tracking cutting

Servo motor: 4kw

Material of blade: Cr12, 58-62 HRC hardness

Cutting power by hydraulic, 11KW with Storage tank

Working pressure: 25Mpa adjustable

Length measuring: Automatic encoder length measuring, brand: Omron

The cutting sequence is also contained and controlled by the same PLC program installed on the above.

Tolerance of length: 3000mm+/- 1.5mm

Hydraulic station:

Hydraulic power: 11kw

Working pressure: 25Mpa adjustable

Solenoid valve: 1 group

Hydraulic oil: 46# hydraulic oil

Contact us if you need more details on Angle Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Forming Machine、Rolling Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

De-coiler→ feeding & guide→roll forming→straighten→post track cutting →manual out table

Feeding & guide→roll forming→straighten→post track cutting

Feeding

Armed adjustable center of the forming rollers and of sufficient length to prevent lateral movement of the strip on its entry to flattener.

Entrance table-guide: Adjustable

Entrance width: 35-130mm (according the final design)

Entrance and guide roller: Diameter is ¢ 76mm, material is sae1045, HRC48-52° Surface with chrome

Forming Section

Profile steel thickness 2.0-5.0mm

Main motor power: 22Kw, AC motor, side motor to save space (Brand: Siemens which made in China)

Machine Voltage, Frequency, Phase: 380 V, 50 Hz, 3Phase

Roll station: 8stations +1 station of straighten

Roller material: Gcr15, 58-62, HRC hardness and chrome plated surface

Shaft diameter: ¢ 85mm material: SAE1045

Machine roll forming speed: 0-30m/min

The min. Roll forming Speed: 0m/min

The maximal roll forming speed: 30m/min

Roll former has leveling bolts in the base for adjust the leveling

Machine base frame adopt H beam welding steel

In the main Roll Forming Machine have 1 button for urgency stop if happen any malfunction.

Transmission: By gear box, joint with coupling, gear inside box structure is bevel gear

Machine stand adopt cast iron

Straighten device:

One station after roll forming,

Function: For revise the end product up and down/ left and right to straightness

Roller material: Roller material: GCR15 quenched 58° -62° Finishing turning CNC

Adjust by hand wheel

To avoid accidents, the drive parts will be covered by protective cover

Post track cutting system

Cutting after forming: Cut the sheet after roll forming to required length

Cutting Type: Hydraulic servo motor tracking cutting

Servo motor: 4kw

Material of blade: Cr12, 58-62 HRC hardness

Cutting power by hydraulic, 11KW with Storage tank

Working pressure: 25Mpa adjustable

Length measuring: Automatic encoder length measuring, brand: Omron

The cutting sequence is also contained and controlled by the same PLC program installed on the above.

Tolerance of length: 3000mm+/- 1.5mm

Hydraulic station:

Hydraulic power: 11kw

Working pressure: 25Mpa adjustable

Solenoid valve: 1 group

Hydraulic oil: 46# hydraulic oil

Contact us if you need more details on Angle Roll Forming Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Forming Machine、Rolling Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Cold steel roll forming machine

Premium Related Products

Other Products

Hot Products

High quality heat insulation roof tile machineNew type high quality aluminium coil slitting machine priceHigh quality MR1000 galvanized sheet corrugated machineEuropean standard High quality steel structure truss purlinEuropean standard most popular aluminum foil/steel coil embossing machineLow Operational Cost Expressway Guardrail Forming MachinePrime quality ppgi roofing sheet/galvanized steel coil /ppgiHigh quality storage rack roll forming machine make AG profileHigh quality double roll forming machine for sale2014 Low Energy Consumption Ridge Cap Roll Forming Machine For TheatreHigh quality aluminum foil coating line,sheet coating lineHigh Quality Quick Interchangeable Purlin Roll Forming MachineHigh Quality Dual roof panel roll forming machineEuropean standard high quality IBR forming machine for roofingVarious customized Roll forming machine priceEuropean standard Top quality slotted glavanized 45 degree angle iron making machine