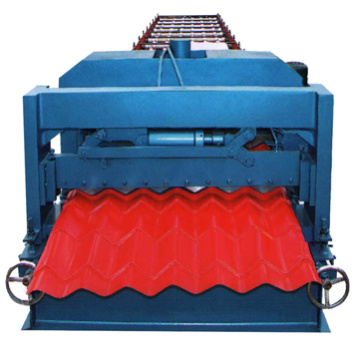

Botou Win-Win Roofing Sheet Glazed Tile Roll Forming Machine

Botou Win-Win Roofing Sheet Glazed Tile Roll Forming Machine

| Min. Order: | 1 |

|---|

| Certificate: | SGS, CE, ISO9001 |

|---|

Basic Info

Model No.: win-win

Product Description

Model NO.: win-win Condition: New Usage: Roof Type: Rolling Machine Feature: Automation Warranty: 24 Months Color: as You Like Certification: SGS, CE, ISO9001 Customized: Customized Transmission Method: Machinery Power Source: Pneumatic Advantage: Easy to Maintenance Forging Forming Method: Mold Forging Power: 380V 50Hz

Working flow:

manual uncoiler-Roll forming machine-computer control system-hydraulic system-forming part-cutting part-discharge table

No

Technical Specification

1

Manual Uncoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand. Loading capacity:1.2T,Inner diameter: 500-508mm

2

Feeding Table

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

3

Main Roll Forming Machine

Material of rollers:45# steel,roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped

4

Hydraulic System

Computer Control Cabinet

Power:5.5kw,Hydraulic oil: 40#

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use

PLC:EURA

5

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12,quenching treatment

6

Output Table

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

Company Introduce:

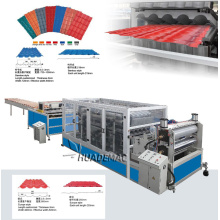

Our enterprise, Botou Win-win Roll Forming Machine Co., Ltd, as the professional and leading manufacturer, can manufacture, design, installation and debug various roll forming machines and metal processing sheet equipments, which produce metal roof wall panel, glazed roof tile, CZ steel purlin, floor decking, roof ridge cap, sandwich panel, roof truss, shutter panel, shutter slat, door frame, guardrail, and metal sheet uncoiler, bending, slitting, cutting, flattening, punching, crimping.

Backed by reasonable design, precision machining and selected material, both our standard and customized machines are characterized by long life span, precise forming and easy operation. With our customers' trust, our machines have been sent to America, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil, etc.

Warmly welcome to China to visit our factory and select the machines you need. Our address,Fuzhuang Industrial Development Zone, Botou City, Hebei Province, China

Our Services

First,we can produce the special machine,send your drawing to us,we can design for you.

Second,if you buy our products,we also can help you to purchase the material,like color roll,the price is lower than you buy by yourself.

Third, we provide a one year warranty and lifelong technical support,we can send our technicians to you to give you on-site training.

Four,engineers available to service machinery overseas.

Five, if you come to visit our factory,we can book the room for you,car pick up to send.

FAQ

1. Q: Are you manufacture or trading company?

A: We are manufacture who was signed in 2008. And our boss has ten years' experience in machinery.

2. Q: When did u start producing roll forming machine?

A: Our company was signed in 2008, and our boss has ten years' experience of machinery.

3. Q: Why should I choose you?

A: We have years' experience to design and provide lower price for customer.

4. Q: How many kinds of products do you produce?

A: We have produced dozens shape of panels including trapizoid, glazed, roof ridge and door panel, and so on for customers during last years. We also provide EPS and rock wool panel line.

5. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Botou, Hebei province. We could pick you up from Cangzhou Station or Beijing airport when you come.

Contact us if you need more details on Glazed Tile Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tile Forming Machine、Roofing Sheet Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

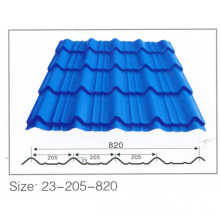

| 1 | Suitable to process | Color steel plate |

| 2 | Width of the plate | 1000mm,1200mm |

| 3 | Roller | 26rollers |

| 4 | Dimensions | 10*1.45*1.51m |

| 5 | Power | 7.5+5.5kw |

| 6 | Thickness of the plate | 0.8-1.2mm |

| 7 | Productivity | 8-10m/min |

| 8 | Material of the cutting blade | Cr12 |

| 9 | Diameter of the roller | Φ70mm |

| 10 | Weight | About 6.8T |

| 11 | Voltage | 380V 50Hz 3phases |

| 12 | Control system | PLC control |

Working flow:

manual uncoiler-Roll forming machine-computer control system-hydraulic system-forming part-cutting part-discharge table

No

Technical Specification

1

Manual Uncoiler

Usage:It is used to support the steel coil and uncoil it in a turnable way. The steel coil is uncoiled by hand. Loading capacity:1.2T,Inner diameter: 500-508mm

2

Feeding Table

Put the raw material(steel plate) through the beach to manufacture and process, it can guarantee that the products are neat, parallel and everything is uniformity. Please refer to the equipment regulation to know the function of locate angle iron.

3

Main Roll Forming Machine

Material of rollers:45# steel,roller surfaces polishing, hard plating , The polished surface and the heat treatment towards the molds also can keep the molding plate surface smooth and not easy to be marked when it is being stamped

4

Hydraulic System

Computer Control Cabinet

Power:5.5kw,Hydraulic oil: 40#

hydraulic oil into the hydraulic oil tank ,the pump drive the cutter machine to begin the cutting job.

The target piece`s length is adjustable and digit of it can be adjusted. Computed mode has two modes: automatic and manual one. The system is easy to operate and use

PLC:EURA

5

Shearing Mechanism

It adopts the hydraulic drive and automatic location to decide the dimension and cut the target products.

Material of blades: Cr12,quenching treatment

6

Output Table

It adopts welded steel and supported roller to transmit the products,which is used to collect the finished products.

Company Introduce:

Our enterprise, Botou Win-win Roll Forming Machine Co., Ltd, as the professional and leading manufacturer, can manufacture, design, installation and debug various roll forming machines and metal processing sheet equipments, which produce metal roof wall panel, glazed roof tile, CZ steel purlin, floor decking, roof ridge cap, sandwich panel, roof truss, shutter panel, shutter slat, door frame, guardrail, and metal sheet uncoiler, bending, slitting, cutting, flattening, punching, crimping.

Backed by reasonable design, precision machining and selected material, both our standard and customized machines are characterized by long life span, precise forming and easy operation. With our customers' trust, our machines have been sent to America, Australia, Russia, India, Sri Lanka, Nigeria, Pakistan, Uzbekistan, Mozambique, Angola, Turkey, Brazil, etc.

Warmly welcome to China to visit our factory and select the machines you need. Our address,Fuzhuang Industrial Development Zone, Botou City, Hebei Province, China

Our Services

First,we can produce the special machine,send your drawing to us,we can design for you.

Second,if you buy our products,we also can help you to purchase the material,like color roll,the price is lower than you buy by yourself.

Third, we provide a one year warranty and lifelong technical support,we can send our technicians to you to give you on-site training.

Four,engineers available to service machinery overseas.

Five, if you come to visit our factory,we can book the room for you,car pick up to send.

FAQ

1. Q: Are you manufacture or trading company?

A: We are manufacture who was signed in 2008. And our boss has ten years' experience in machinery.

2. Q: When did u start producing roll forming machine?

A: Our company was signed in 2008, and our boss has ten years' experience of machinery.

3. Q: Why should I choose you?

A: We have years' experience to design and provide lower price for customer.

4. Q: How many kinds of products do you produce?

A: We have produced dozens shape of panels including trapizoid, glazed, roof ridge and door panel, and so on for customers during last years. We also provide EPS and rock wool panel line.

5. Q: Where is your factory located? How can I visit there?

A: Our factory is located in Botou, Hebei province. We could pick you up from Cangzhou Station or Beijing airport when you come.

Contact us if you need more details on Glazed Tile Machine. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Tile Forming Machine、Roofing Sheet Machine. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : glazed tile roll forming machine

Premium Related Products

Other Products

Hot Products

High quality heat insulation roof tile machineNew type high quality aluminium coil slitting machine priceHigh quality MR1000 galvanized sheet corrugated machineEuropean standard High quality steel structure truss purlinEuropean standard most popular aluminum foil/steel coil embossing machineLow Operational Cost Expressway Guardrail Forming MachinePrime quality ppgi roofing sheet/galvanized steel coil /ppgiHigh quality storage rack roll forming machine make AG profileHigh quality double roll forming machine for sale2014 Low Energy Consumption Ridge Cap Roll Forming Machine For TheatreHigh quality aluminum foil coating line,sheet coating lineHigh Quality Quick Interchangeable Purlin Roll Forming MachineHigh Quality Dual roof panel roll forming machineEuropean standard high quality IBR forming machine for roofingVarious customized Roll forming machine priceEuropean standard Top quality slotted glavanized 45 degree angle iron making machine